Background information

The dream of your own PC case, part 1: The construction

by Kevin Hofer

David's dream of building his own PC case is getting closer and closer. The polymechanics apprentice from Aargau is building his own case together with his colleague Viktor and I am accompanying them. Today I am visiting him at his training company Schwarz AG Feinblechtechnik and looking over his shoulder as he builds the case.

I have to hurry to keep up with David in the halls of his training centre. Despite his steady pace, he pauses briefly every now and then. He runs his hand gently over the metal sheets he has produced and gives them a scrutinising glance. Then he turns his focus back to his goal: explaining to me how he manufactures his PC housing.

Polymechanic David builds a PC case together with designer Viktor for an in-depth project. Last time I spoke to Viktor about the design in CAD.

David leads me to a work table that he has prepared. There are various tools and parts on it. He is holding a notepad in his hands. He has written down everything he wants to tell me. The note is his guide for my visit.

After a quick glance at it, David explains the various work steps to me. He has decided to laser cut his housing instead of punching it and explains the advantages and disadvantages of both methods. Laser cutting allows for more optimal contours. On the other hand, some of the edges are rounded when punching. This provides better corrosion protection. This is very important to him. He mentions it again and again. That's why he would now use punching instead of lasering. To show me the difference, he shows me laser-cut and punched parts.

David meticulously goes through his list. He has opted for galvanised steel as the material. This is easier to work with than aluminium, but it weighs more. But that doesn't bother him: he mainly wants to use his PC as a stationary device.

He made the feet from chrome steel. This is visually more attractive and strong enough for the housing. The requirements are high: in the end, the part will certainly weigh over 13 kilograms.

David continues to work through his list. After lasering, he has to make the thread pull-throughs. He could actually have done this directly during punching. Unfortunately, he didn't realise that. That's also part of the in-depth work: learning new things.

After that, bending, pressing and painting are on the programme. The final stage is final assembly. Unfortunately, David can't show me everything today. But he is keen to show me his favourite part of the job, the bending.

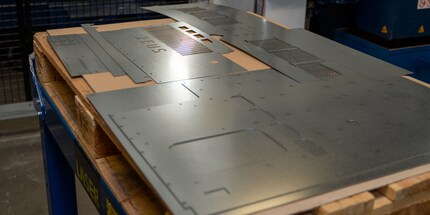

He leads me on to his workstation. On the way there, we pass the laser machine he used to cut the parts for his PC. And then I catch sight of the parts he made earlier. A smile on his lips - and again he runs his hands over the galvanised steel. But I can't marvel at the parts for long. David gestures for me to follow him. The bending continues.

Bending requires a lot of concentration, says David. You also need to know a lot. He edges the PC feet. He stares mesmerised at the screen of his workstation and makes various settings. He explains to me exactly what he is doing. I only understand what he's saying. Not because he's explaining it badly: It's the first time I've seen a machine like this. I didn't realise how much work is involved in bending metal parts and what you need to know to do it.

But before David can start, he has to clamp the correct punch and die into the machine. Then everything is ready. He thinks about which side he needs to feed into the machine first. He then places his chrome steel part on the mould and presses the punch. This presses the PC foot into shape. David measures the angle. He is not yet satisfied. Everything has to be exactly right. He makes further adjustments and bends. Now he is satisfied. Just three more bends and then the first foot is finished.

Unfortunately, I can't stay for the rest of the work. David has to get on with his actual work at the teaching company. Anyway, the fact that he is allowed to show me round his company is an exception. He has to make the PC housing in his spare time when the machines are free.

Before I leave, I want to know from David how much time he reckons the fabrication will take. At least five hours, he says. He's not quite sure how expensive the case would be if it were a contract job. The fabrication alone would cost around 1000 francs for a batch size of one, including materials. That doesn't include all the planning and construction. That would be an even bigger item.

I am impressed. All the passion that David and Viktor put into their work. They get the best out of their resources. They form a perfect team: Viktor with his CAD skills and David with his precise way of working. In addition to design and fabrication, they also keep an eye on economic factors - even if these are only secondary. And the great thing about their project: in the end, they not only learn something, but also fulfil a dream of their own.

David promises to write to me when he's finished. After a few weeks of silence, I receive an email. He hasn't been able to finish the housing yet. Unfortunately, the machine for bending large parts is always busy. David doesn't even know whether he'll be able to finish the housing at all during his apprenticeship, which runs until the summer.

Are David and Viktor falling victim to their own ambition? To save weight and material, they decided to make the bottom, front and top in one piece instead of three smaller ones and then rivet them together. This could now be their downfall. I hope that David gets round to folding at some point. It would be a shame for all the work the two of them have put into the case.

From big data to big brother, Cyborgs to Sci-Fi. All aspects of technology and society fascinate me.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all