Guide

The sleeper PC project: one ugly duckling

by Kevin Hofer

A scratch build is the dream of many PC enthusiasts - not just buying and installing the components for a PC, but also making the case yourself. Two apprentices from the Baden Vocational College embark on this adventure and I accompany them on their journey.

"Interview request": This is the subject of the Outlook message that pops up on my desktop. Interview request? I don't have any open interviews at the moment. Is anyone interested in me? Yes, Viktor and David from the vocational college in Baden want to interview me about case modelling. I feel honoured. But at the same time, I wonder if I'm the right person for the job. My only major project to date has been the Sleeper PC.

I explain to them that I don't have that much experience in case modding. But they still want to do the interview with me. That's almost an accolade.

In further email correspondence, it becomes clear what the two of them want to do with the interview: they have to conduct an interview on a relevant topic for their dissertation. However, I find their project much more exciting than the interview with me: As polymechanic apprentices, they want to use their expertise to build their own PC case.

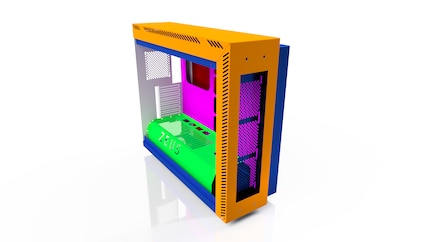

A few days later, I meet the two ambitious PC case builders for an interview. Viktor, who specialises in construction, i.e. designing CAD models, shows me the case design. He designed it together with David, who specialises in manufacturing. I realise that I can't just let them go. I want to know what's going to happen with them and their case. I offer them the opportunity to use our relationship with Alphacool at digitec and organise the components for their water cooling system. In return, I can accompany their project with articles.

The two of them agree with a happy smile. I turn from interviewee to interviewer and question Viktor, the designer.

How did you come up with the idea of making your own housing?

Viktor Weilenmann: The idea came from David. As he is an apprentice at a sheet metal processing company, he has the necessary machines at his disposal. I had thought about doing something with PCs for my specialisation project. As I work as a design engineer, I don't have access to machines. But I wanted to do a job where I could make something.

I really liked David's idea. I suggested that I use my CAD skills to help him design the housing. He would then take over the production.

**What was the basic design idea?**

We first sketched out a few concepts and thought about what we could produce in the limited time available for the in-depth work. We decided to make a midi tower.

**Where did you get your inspiration from?**

We browsed through PC builds on Reddit and YouTube. We came to the conclusion that we cool our system with water. There are already some very good cases out there. I orientated myself on my Define R6 from Fractal Design in terms of material thickness, position of the components and the other dimensions.

**What did you do first?**

Before we officially started the in-depth work, I roughly designed a PC housing. It was a kind of brainstorming session directly in CAD. I made a note of things that I needed to bear in mind for the actual project. David and I then made a sketch and decided what our case should roughly look like.

**How did you proceed from there?**

With the concept and my notes from the first design, I started to create the actual housing in Inventor Professional 2020 - a 3D CAD software programme.

What were the difficulties in the construction?The most difficult thing was to position the mainboard so that the I/O panel on one panel and the PCI-E slots on the other panel would fit together. I found several sources of I/O panel sizes on the Internet that did not match. So I decided to use scale models from Grabcad.com to determine the position.

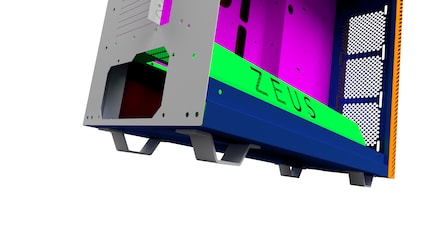

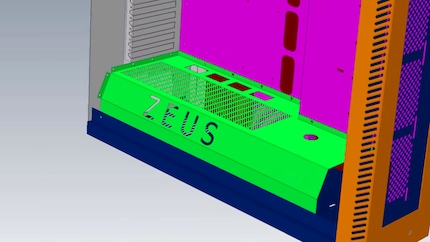

We also had difficulties with the cover. This should cover the fan slots and have room for an Infinity Mirror at the front. We didn't know how to screw the cover on. We decided to rivet spacers to the inner panel and attach a press-in nut to them. This ensures the position and spacing. We used DIN 464 knurled screws to minimise the amount of protruding parts.

**What was particularly easy?**

The cut-outs for the fans on the sheet metal and the feet were quickly made.

Building the water cooling system in CAD was also easy, as Alphacool provides all 3D models of their products on their website.

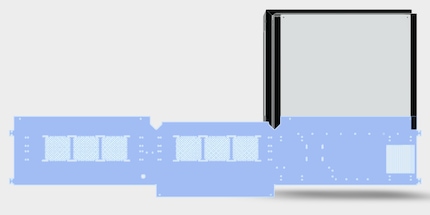

**You are planning the bottom, front and top from one sheet metal part. What is the reason for this?**

We want to save riveting points. Riveting requires so-called sheet metal tongues, where the sheet metal parts are riveted together. That doesn't look so clean. If we produce the three parts in one, we can achieve clean bends without rivets.

**How satisfied are you with the design?**

I'm happy with the case. It took a lot of time to finalise the design. I would focus on a smaller case next time, as I find small, handy ITX PCs very interesting.

**How long did it take you to build the case?**

I invested around 60 hours, of which around eight hours were for production drawings. If I were to design a housing from scratch now, I would definitely be faster. I had to make a lot of adjustments during the design process. With the knowledge I've gained, I can avoid some problems right from the start.

Alphacool contributes the following components, among others:

In addition, there are various fittings.

The finished housing is not as colourful as in the animation. The individual parts are only coloured so that Viktor can tell them apart in CAD. The case is to be painted black, the interior illuminated in white with white tubes and chrome-coloured fittings. The guys want to create a lightning bolt shape on the Infinity Mirror. Hence the name of the case: Zeus. David is a fan of Greek mythology.

Next time I visit David in his workshop and look over his shoulder as he makes Zeus.

From big data to big brother, Cyborgs to Sci-Fi. All aspects of technology and society fascinate me.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all