Best Purefil products in the 3D printer filament category

On this page you'll find a ranking of the best Purefil products in this category. To give you a quick overview, we've already ranked the most important information about the products for you.

1. Purefil Filament

The Purefil filament line was specially developed for private use. The use of high-quality raw materials creates a 3D printer filament, which is particularly easy to process. A state-of-the-art manufacturing process achieves very low manufacturing tolerances, resulting in convincing printing results with all FDM 3D printers. Each spool is vacuum packed in a high quality bag. In principle, PLA filament or polylactide is biodegradable, whereby certain environmental conditions are necessary, which can usually only be found in industrial composting plants. In nature, PLA normally does not decompose. No PLA filament or printed parts from PLA should therefore be composted.

2. Purefil abs filament

By using high-quality raw materials, a 3D printer filament is created that is particularly easy to process. A state-of-the-art manufacturing process achieves very low production tolerances, resulting in impressive printing results with all FDM 3D printers. Each spool is sealed in a high-quality bag.

- Made in Switzerland

- Low diameter and roundness tolerances

- Easy to print

Polylactic acid (PLA) is a polymer that consists, among other things, of lactic acid molecules. A heated bed is advantageous for PLA filament, but not strictly necessary. It is recommended to use an air cooler when processing PLA filament. Furthermore, PLA is characterized by significantly more pleasant odor properties compared to other plastics during processing.

3. Purefil PETG Filament

The purefil PETG filament is a high-quality solution for 3D printing, specifically designed for use with FDM printers. It comes in convenient refill packs that do not require spools, which not only protects the environment but also promotes the reuse of plastic spools. This filament is characterized by its clarity and robustness, making it an ideal choice for a variety of applications. The use of top-quality raw materials and a precise manufacturing process ensure low manufacturing tolerances, leading to excellent printing results. The PETG filament is odorless and offers high impact resistance as well as flexibility, making it particularly user-friendly. To achieve optimal results, it is important to pre-dry the filament before processing to avoid bubble formation. Storage should also be dry and airtight to maintain the quality of the material.

- Eco-friendly refill packs without spools

- Excellent printing results due to low manufacturing tolerances

- High impact resistance and flexibility

- Odorless and easy to process

- Important pre-treatment: pre-dry before processing.

4. Purefil PLA filament

The use of high-quality raw materials creates a 3D printer filament that is particularly easy to process. Using a state-of-the-art manufacturing process, very low manufacturing tolerances are achieved, leading to convincing printing results with all FDM 3D printers. Each coil is sealed in a high-quality bag.

- Made in Switzerland

- Small diameter and roundness tolerances

- Easy to print

Polyactide is a polymer that consists of lactic acid molecules, among other things. We currently have PLA filament 1.75 mm and PLA filament 2.85 mm in our range. A heated bed is advantageous for PLA filament, but not essential. We recommend using an air cooler when processing PLA filament. Furthermore, PLA is characterized by a much more pleasant odor during processing than other plastics. However, the temperature below which PLA starts to soften is relatively low. Even at high temperatures in summer, PLA parts can deform. As a starting material, PLA is basically biodegradable under special conditions. However, the final product contains pigments and additives, which means that PLA parts still have to be disposed of in the garbage and not in the garden.

This filament meets the compositional requirements of European Regulation No. 10/2011 on plastic materials intended for food contact.

Characteristics:

- Minimal shrinkage

- Little delay

- Low water absorption

- Soluble in many organic solvents

- High UV resistance

- Low flammability

- Heat resistance up to approximately 60°C

PLA filament or polylactide is biodegradable, but certain environmental conditions are necessary, which can usually only be found in industrial composting plants. PLA does not normally decompose in nature, so we do not recommend composting PLA filament or printed parts made of PLA.

5. Purefil abs filament

By using high-quality raw materials, a 3D printer filament is created that is particularly easy to process. A state-of-the-art manufacturing process achieves very low production tolerances, resulting in impressive printing results with all FDM 3D printers. Each spool is sealed in a high-quality bag. Made in Switzerland, with low diameter and roundness tolerances. Polylactic acid is a polymer that consists, among other things, of lactic acid molecules. A heated bed is advantageous for PLA filament, but not strictly necessary. Additionally, PLA is characterized by significantly more pleasant odor properties compared to other plastics.

6. Purefil PETG filament

The Purefil PETG filament is an eco-friendly solution for 3D printing, offered in convenient refill packs. These packs are designed to be delivered without spools, promoting the reuse of existing plastic spools and thereby contributing to waste reduction. Made from high-quality raw materials, this filament provides easy handling and excellent printing results for all FDM 3D printers. The state-of-the-art manufacturing process ensures low manufacturing tolerances, further enhancing print quality. PETG is known for its clarity, durability, and odor neutrality, making it an ideal choice for various applications in 3D printing. To achieve optimal results, it is important to dry the filament thoroughly before processing to avoid bubble formation. Storage should also be dry and airtight to maintain the quality of the material.

- Eco-friendly refill packs without spools to reduce waste

- Made from high-quality raw materials for easy processing

- Low manufacturing tolerances for impressive print results

- High impact resistance and flexibility for versatile applications

- Odorless and transparent, ideal for various printing projects.

Purefil PETG filament

PETG, 1.75 mm, 1000 g, Grey

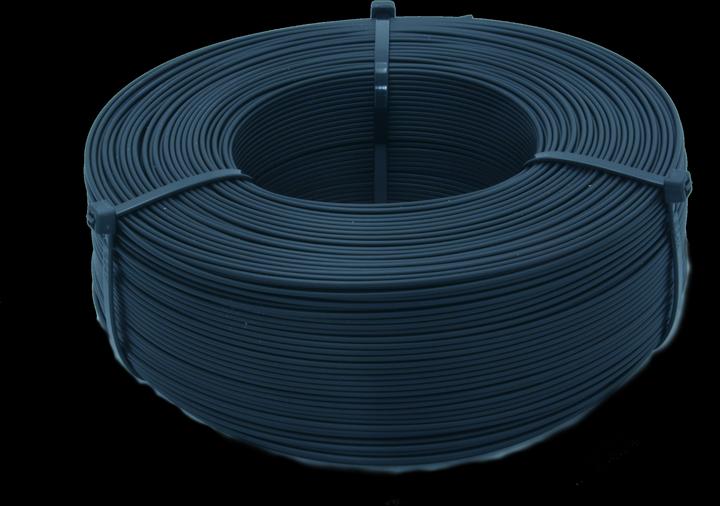

7. Purefil COC filament

The Purefil Refill Packs contain wound filament that is delivered without a spool. This product allows you to refill the Purefil plastic spools with new filament, eliminating the need to dispose of the empty spool and saving resources.

By using high-quality raw materials, a 3D printer filament is created that is particularly easy to process. A state-of-the-art manufacturing process achieves very low manufacturing tolerances, resulting in impressive printing results with all FDM 3D printers. Each refill pack is sealed in a high-quality bag.

- Made in Switzerland

- Low diameter and roundness tolerances

- Easy to print

COC is a polyolefin that, unlike the semi-crystalline olefins PP or PE, is amorphous and therefore transparent. This makes COC significantly easier to process in the FDM method than PP or PE. Cyclo-Olefin-Polymer has excellent transparency and is therefore often used for optical applications. COC has high hardness, strength, and stiffness, as well as low density. Its chemical resistance is very good. Due to its excellent biocompatibility, the material is often used in the medical field. The material has very low water absorption and excellent water vapor barrier properties. This filament meets the requirements of the European Regulation No. 10/2011 on plastic materials intended for food contact.

8. Purefil Filament POM

By using high-quality raw materials, a 3D printer filament is created that is particularly easy to process. A state-of-the-art manufacturing process achieves very low production tolerances, resulting in impressive printing results with all FDM 3D printers. Each spool is sealed in a high-quality bag.

- Made in Switzerland

- Low diameter and roundness tolerances

- Easy to print

POM is a semi-crystalline thermoplastic. It is one of the typical engineering thermoplastics with good mechanical properties, high dimensional stability, and excellent sliding and wear behavior. POM filament is therefore one of the preferred construction materials, for example, for snap-fit connections and gears. The operating limits range from approximately -40 to 100 °C for continuous use, and up to 120 °C for short-term exposure.

9. Purefil GF20

The purefil filament line was specially developed for private use. The use of high-quality raw materials results in a 3D printer filament that is particularly easy to process. Thanks to a state-of-the-art manufacturing process, very low production tolerances are achieved, which leads to convincing printing results with all FDM 3D printers. Each spool is sealed in a high-quality bag.

10. Purefil abs filament

The use of high-quality raw materials creates a 3D printer filament that is particularly easy to process. Using a state-of-the-art manufacturing process, very low manufacturing tolerances are achieved, which leads to convincing printing results with all FDM 3D printers. Each coil is sealed in a high-quality bag. - Made in Switzerland - small diameter and roundness tolerances - easy to print Acrylonitrile-butadiene-styrene is a copolymer in which, among other things, butadiene is grafted onto the molecular chains. This makes the ABS much more impact-resistant than before the modification. The proportions are generally as follows: 15-35% acrylonitrile, 5-30% butadiene and 40-60% styrene. ABS is mainly used for the production of household and consumer goods. We currently have ABS filament with a diameter of 1.75mm in our range. In order to be able to print ABS filament, you must first m.