1000 Raspberry Pi (and why the 7" display was sold out)

At Digitec Galaxus we like making things ourselves. This occasionally requires quite a bit of perseverance, as our showroom screens nicely demonstrate. This is a story about engineering at Digitec Galaxus and about hundreds of Raspberry Pi.

We’ve got 8 stores with a showroom. These are all equipped with 105 screens, each of which are neatly sunk into the display tables on which the products are presented. The screens provide customers with additional product information. Now, all 840 (you’re welcome) of them have been upgraded.

So what’s changed? Not much, really. Sorry to disappoint you but this is a field report that's about how drive and perseverance can lead to great solutions.

If you’d like a sneak peek behind the scenes at Digitec Galaxus and want to find out what all of this has to do with Raspberry Pi, Cornelia Hauri is the person you’re looking for. Cornelia is project leader at Digitec Galaxus. She smiles when I ask her about the project. After more than two years it has been successfully completed. But first things first.

First attempt: Tablets

It all started with a new showroom concept. The vision behind it: to create custom-made tables that display products and allow customers not just to look but also to feel the product. Each table should present a display model and be equipped with a screen that provides up-to-date product information, the price and product ratings from the community.

So each table was fitted with a tablet. These first-generation devices worked astonishingly well. But after one year, it was over. The tables simply weren’t made for non-stop use. The batteries swelled up one by one and all devices gave up the ghost.

Meanwhile, the number of stores with a showroom had grown to eight. And with more showrooms came more display tables. But the acquisition of thousands of tablets just wasn’t feasible. An alternative solution was needed.

Second attempt: ePaper

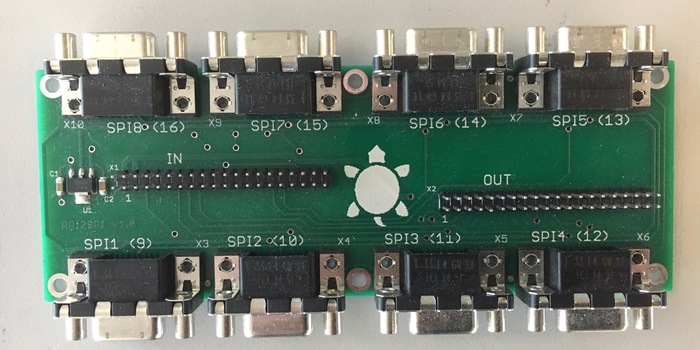

It was decided to switch to ePaper displays. David Creel and Tudor Zaharia (engineering) specifically created an interface board for the Raspberry Pi. Using two boards, a single Raspberry could drive a cluster of sixteen screens.

The original UI concept envisaged a swiping motion – like you do on your smartphone – to scroll through texts. Unfortunately, ePaper screens (or rather the flash chips used to drive them) are not designed for frequent image changes. A rough calculation showed that after four months max, all screens would break. This called for the development of a new, static design: If the displayed images only changed every few minutes, the displays would last a lot longer.

So the software was modified and a prototype was developed. Everyone was hopeful when the first pilot test was launched at one of the stores soon after. The joy did not last long. Within one week, five screens had been destroyed by customers – by accident, of course. All it had taken to break the screen was placing an SLR camera on it. As it later turned out, the custom-made Plexiglas bezels were simply not strong enough. They had given in under pressure and made the screens burst.

A dry spell ensued and we went from ePaper back to paper. That sounds funnier than it actually was. Every day, the store employees had to print out current information and prices for each product on display. The pressure was on for the project team. They needed to act fast if they ever wanted to show their faces in the store again.

Third attempt: Raspberry Pi

Firstly, a new, more stable bezel had to be developed. This time, David left nothing to chance: Metal was used and the design was tested in the simulator. At the same time, in September 2015, Raspberry launched a matching screen for the Pi. At 7" it was not only the perfect size but also featured a very good resolution and a touch interface – perfect! Together with the new bezel, this was bound to work.

Well not everything went as smooth as planned. The mount – the plastic cover between the table and the screen – had to be made of scratch-proof, resistant plastic. It took 5 attempts in total to find the right material. The low point for Cornelia was opening the parcel containing 1000 pieces – they had all been scratched in transport. Finally, a Swiss company delivered the mounts in the desired quality.

In the pilot test, the new solution stood the test both visually and technically. Each table now features a Raspberry Pi model 2, a 7" display and a 5V power supply. Over the course of six months, only one defect was recorded in the test shop. In addition, the Raspberries automatically switch off in the evening and wake up when the store opens in the morning. They’re sturdy, low-maintenance and cost-effective – that’s how we like it! The solution was rolled out in all stores.

By the way, all devices were installed and assembled by our very own shop employees. On top of their daily business, they spent every spare minute equipping the tables. A big thanks to the team!

PS: Now all your Raspberry Pi fans out there know why the 7" display was sold out for months at digitec.ch: We needed them all for our stores. So sorry! ;)

More about engineering at Digitec

I'm the master tamer at the flea circus that is the editorial team, a nine-to-five writer and 24/7 dad. Technology, computers and hi-fi make me tick. On top of that, I’m a rain-or-shine cyclist and generally in a good mood.

Everything you'd usually read on a news portal or in the newspaper can be found here, directly from the source: annual figures, new services, our efforts for greater sustainability, sales trends and so on.

Show all