Best Laing products in the Water cooling pumps category

On this page you'll find a ranking of the best Laing products in this category. To give you a quick overview, we've already ranked the most important information about the products for you.

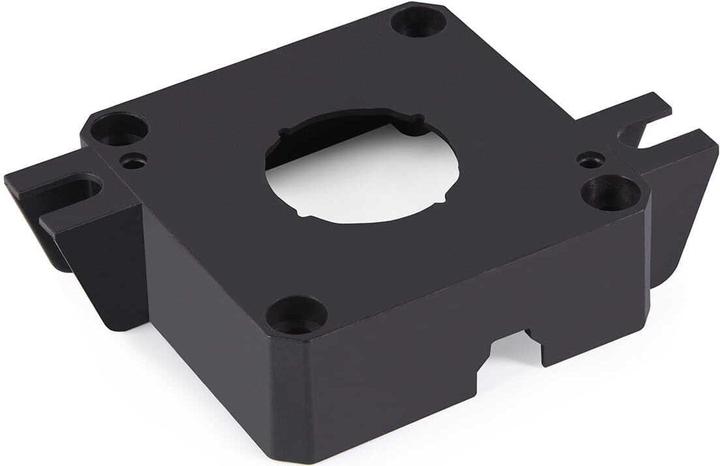

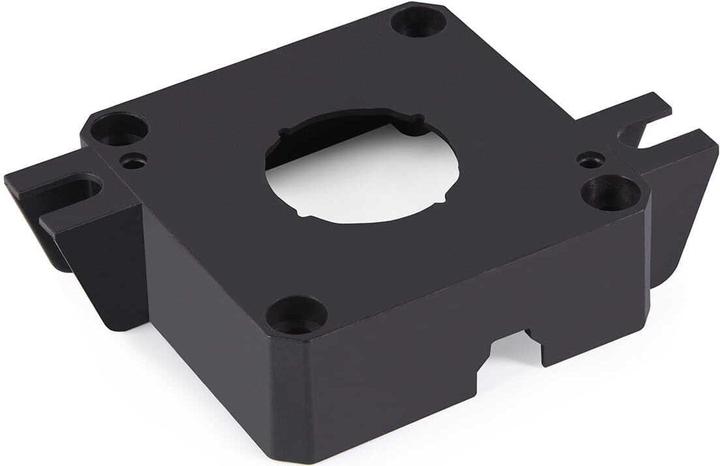

1. Laing Motor housing DDC pump with bracket

For Laing DDC pumps, not only a suitable cover is required, but also a compatible pump housing. This pump housing features two brackets that allow the pump to be mounted on a pump holder. The pump housing is compatible with all original Laing DDC pumps.

2. Laing DDC pump 12V DDC-1RT Plus with 2xG1/4 male thread

This pump is the first pump in the world to be used in mass-produced water-cooled workstations and is ideal for water-cooling processors and electronic components. Due to its size and performance, it can also be used in a variety of applications. This DC pump is an electronically commutated ball motor pump, with running times of well over 50,000 hours at 12 volts. The only moving part on a ball motor pump is a spherically shaped rotor/impeller unit supported on an ultra-hard, wear-resistant ceramic bearing ball. A conventional shaft with shaft bearings and shaft seals is not available. The spherical bearing of the rotor/impeller unit on the ceramic bearing ball offers a number of advantages: The occurrence of bearing play - and thus an increase in noise - is not possible due to the principle. The pump thus remains quiet throughout the entire running time. The bearing is self-adjusting. It is lubricated directly by the pumped medium (wet rotor pump). Maintenance is therefore not necessary. Since the rotor is always held magnetically in the intended position, smaller dirt particles do not pose a problem. Normally it is not possible to block the pump. Even after a longer standstill a safe start-up is ensured. The permanent magnetic rotor/impeller unit is driven by a magnetic field generated by the surrounding stator. This is completely built around the rotor. With 38 mm, the complete pump is thus only slightly higher than the stator itself. It therefore fits easily into all standard PC, barebone and mini PC housings. A separate magnetic shielding is normally not necessary. The spherical motor principle enables economical operation with comparatively high power output. By varying the voltage, the DDC DC pump can be easily controlled over a wide power range. All parts in contact with the medium are completely corrosion resistant.

3. Laing Brass pump attachment 1/2 IT

Spare part for the Laing D5 pump 12V D5-Vario and D5-Solar. Note: Also compatible with all other Laing D5 pumps.